We have been in the appliance components business since 1967.

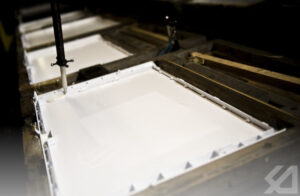

Innovative Production

The top-surface production is carried out on two interchangeable lines with friction rollers. The assembly parts move on those two lines. The different parts are glued with a two-components resin, using 4 six-axis anthropomorphous robots.

Very specific assembly lines and parts (which can be modified according to the client’s requirements) and continues synergy of the various departments, allow us to produce batches of different size. Moreover, we are able to deliver four different models at the same time.

It should be noted that production changes occur without production downtime, which enables us to implement a policy of cost reduction and to guarantee just-in-time supplies.